Environment

Nowadays, the challenges faced by companies are numerous and affect all sectors, without exception, and they do not only consist of increasing sales and capital. On the contrary, in an industrial world where issues related to the quality of the final product and those concerning sustainability are becoming more pronounced every day, everyone must do their part.

From a production standpoint, ensuring procedural compliance is not only a necessary capability for the company itself (in order to organize and optimize its internal processes), but above all an indispensable requirement and a guarantee of reliability in front of the customer. Targeted studies have now widely demonstrated the increasingly frequent adoption of eco-friendly behaviours by a large number of Italian and European consumers who, when possible, do not hesitate to choose sustainable products over others. The awareness and behavioural habits of the people are fundamental for achieving concrete results on a large scale. The imperative must be to think not in terms of a ‘long-term future’, but what has been defined as a ‘long-term present,’ as it is no longer possible to postpone problems indefinitely.

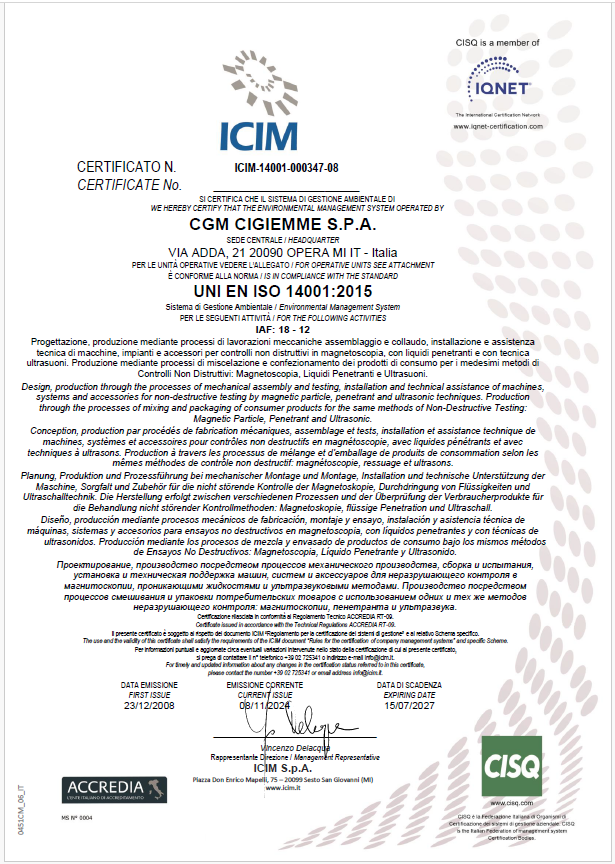

CGM aligns with this need through the attainment of ISO 14001 certification since 2008, recently renewed along with ISO 9001 (obtained in 1997), certifications recently extended to the new local production facility at Via Adda 20. Their importance is certainly not secondary: given the alarming data that experts have collected in recent years about the critical conditions of our planet, today more than ever, attention and respect for the environment must be among the founding principles of corporate policy. For this reason, CGM’s commitment has always been at the forefront and is realized in various ways, including:

- The packaging in cardboard and wood is recyclable, while the primary packaging for powders and liquids is made of at least 70% recycled plastic, well in advance of the PPWR Packaging Regulation, which mandates a minimum percentage of 65% by January 1st, 2040.

- Whenever possible, wooden crate packaging is avoided in favour of cages or simple wrapping.

- The high-consumption workshop lamps have been replaced with LED lighting.

Regarding the first point, the adoption of sustainable packaging, CGM had the pleasure and honour of being among the winners of the 2022 CONAI (National Packaging Consortium) Award for eliminating the presence of virgin plastic in both 10-liter and 5-liter cans. Recently, we have extended the use of recycled plastic to jars containing wet magnetic powders (K) and coupling pastes for ultrasonic testing. In the last four years, by purchasing recycled plastic packaging, we have helped to reduce the amount of first-use plastic introduced to the market by about 14 tons (equivalent more or less to the weight of 9 cars) and to remove about 10 tons (equivalent to the weight of two African elephants) of plastic waste.

As proof of our company’s dedication to addressing such issues, we are proud to add this recognition to the one already obtained in 2019: we have no doubt about the importance of the container, as it ‘tells’ and promotes the quality of the content.

As a manufacturer of industrial products, we are well aware of the risks arising from the incorrect handling of hazardous chemicals, both for the environment and human health. As a general principle, CGM’s policy is centred on communication aimed at maximum transparency towards stakeholders: especially regarding the characteristics of the substances used in the composition of its products and consequently the related methods of use, CGM provides all the necessary technical and safety documentation.

One example for all: the disposal of contaminated containers must follow a precise procedure that safeguards the healthiness of the environment. Such containers are to be considered special waste in the strict sense of the word, and must therefore be disposed of in accordance with precise regulations, since the products they contain consist essentially of pollutants (surfactants, petroleum hydrocarbons). Nor is it possible to devise expedients to dispose of the empty packaging once the product has been used: in fact, washing it in abundance with water does not solve the problem, since the washing liquids do not comply with the limits imposed by current national standards (e.g. T.U.A.).