Magnaflux test

The Magnaflux test or magnetic dye test is a non-destructive testing method, better known as Magnetic Particle Testing.

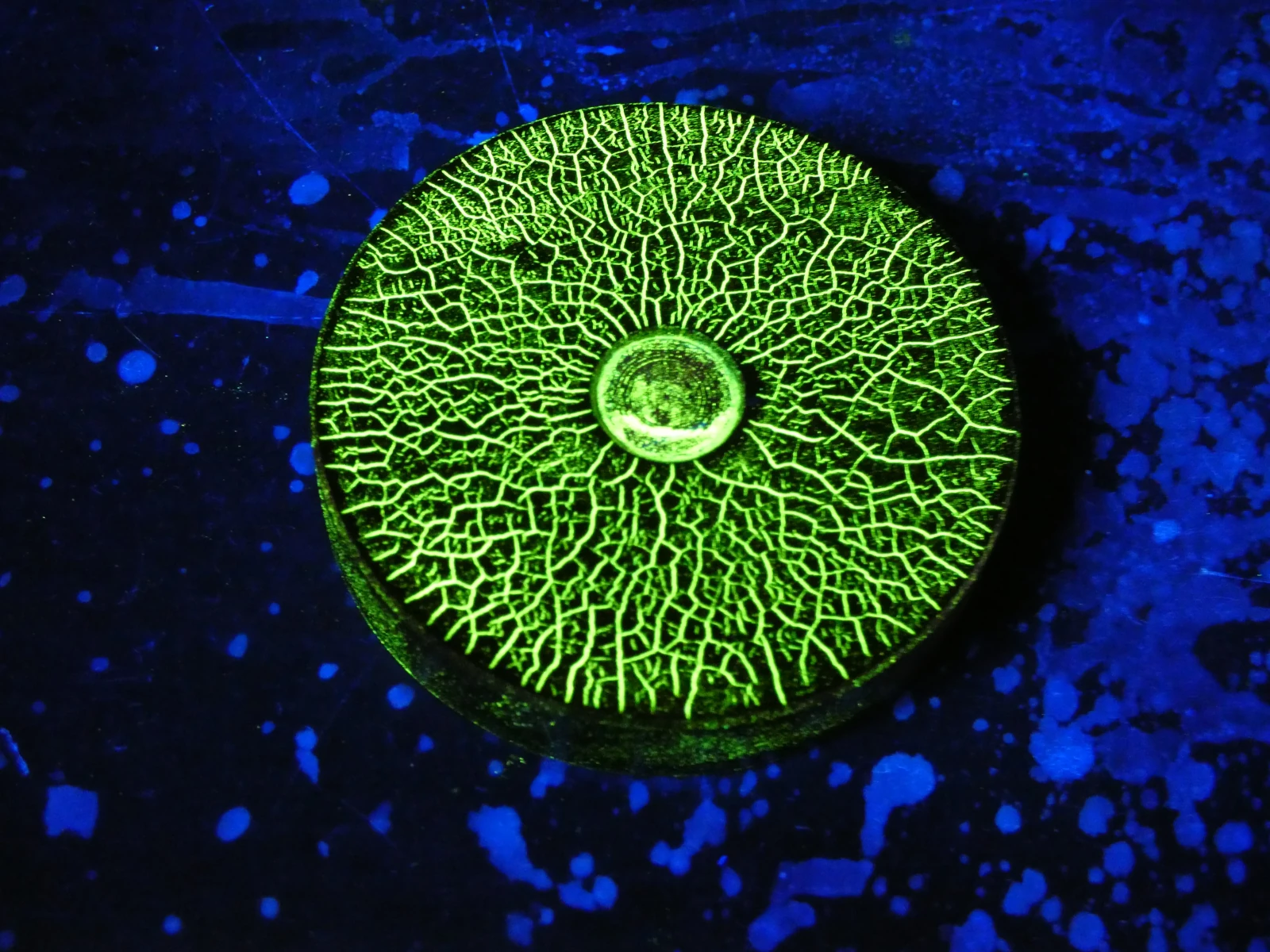

It is applied to ferromagnetic parts after or before machining (and/or after welding) and is used to highlight possible surface and sub-surface discontinuities in the form of small cracks or fissures. As these types of defects can sometimes be difficult to see with the human eye, a method involving coloured or fluorescent magnetic particles has been implemented to highlight possible processing anomalies.

The Magnaflux test can only be performed on metal components that can be magnetized. Their size can vary, even considerably, from simple screws or small bearings to railway wheels and axles or aircraft landing gear.

There are two types of methods: “in continuous” and “residual magnetism”. In the first case, the magnetic powder must be applied at the same time as the magnetic field is applied, in order to use the moment of maximum flux density in the part under inspection in relation to the magnetizing force applied. In the second case, the magnetic powder must be applied after the part under inspection has been magnetized, thus exploiting the residual magnetism in the part.

For more than 65 years, CGM CIGIEMME S.p.A. has been designing and manufacturing all types of Magnetic Particle Testing equipment, from simple yokes and different types of electromagnetic generators to customized systems to meet the most diverse requirements. In addition, CGM can supply all types of magnetic powder (wet or dry method), colour-contrast or fluorescent, plus a wide range of accessories useful for control procedures.