Magnetic particle testing MT

What is Magnetic Particle Testing (MT)?

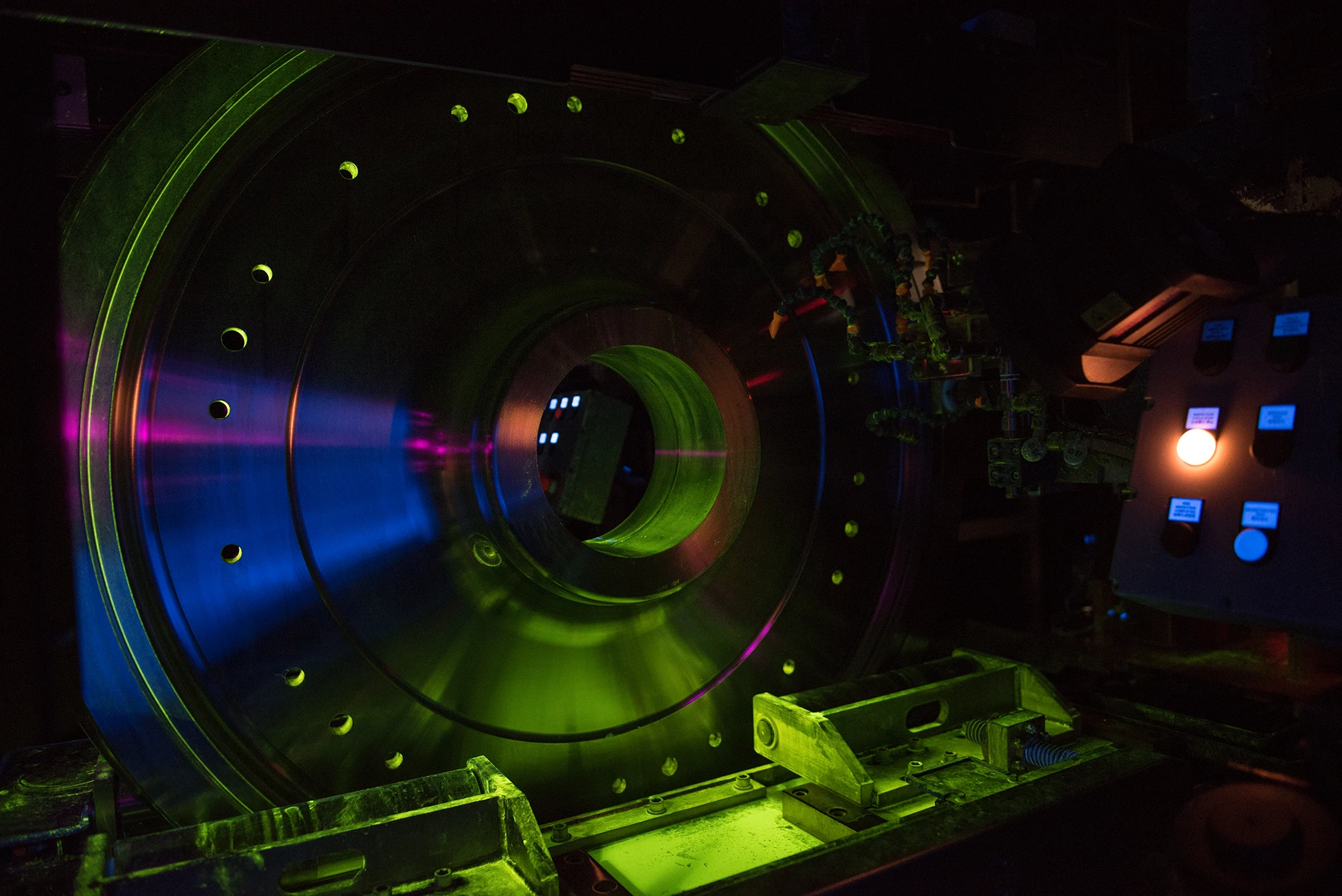

Magnetic Particle Testing is a widely used non-destructive technique that allows the detection of discontinuities emerging from the surface or located, within certain limits, below it (sub-surface) only in parts made of materials susceptible to being magnetized. In practice, the area to be examined is magnetized and then sprinkled with magnetic particles, in the form of powder or liquid suspension, which are attracted to the areas of the surface where the discontinuities generate a "scattered field" forming visible indications, depending on the type of powder used, in white light or black light. Magnetic Particle Testing is therefore based on magnetism. In physics, magnetism is the phenomenon by which a body (made of particular minerals, such as magnetite) is able to attract other bodies containing iron, cobalt or nickel when positioned near its extremities and also to transmit this ability to other materials. Non-ferromagnetic materials such as aluminium alloys, magnesium alloys, copper and its alloys, titanium and its alloys, austenitic stainless steels cannot be tested by this method.

Powders can be visible or fluorescent type and are available for both dry and wet methods. In the dry form the magnetic powders are used as manufactured and are normally of the type visible in white light2. They are available in a wide variety of colors including red, gray, yellow, blue and black, so that the operator can always choose the one that provides the best possible contrast with respect to the surface to be inspected. Dry powders are used with portable or mobile equipment and provide better sensitivity towards discontinuities located under the skin. The size (granulometry) of the particles that make up dry powders is typically between 50 and 300 μm. Dry powders are disposable, that is, they cannot be reused after the first use. In the wet form, magnetic powders are suspended in a liquid, water or oil, and can be either of the type visible in white light or black light. Wet powders visible in white light are red or black, while those visible in black light are fluorescent3 with a very bright yellow-green color and must be observed in a suitably darkened environment. The suspension vehicle consists of water or an oil (distilled from petroleum) with a high flash point. When using water as the suspension vehicle, it is necessary to add a surfactant (wetting agent) to facilitate the suspension of the powders. Wet particles are generally used with fixed equipment that involves the reuse of the magnetic suspension and provide better sensitivity towards very thin surface discontinuities; however, they are also available in spray cans. The particle size of wet powders is generally between 8 and 20 μm, since larger particle sizes are difficult to keep in suspension and in the drainage phase they tend to merge together forming alignments (the so-called drainage lines) that can be mistaken for true indications. This phenomenon is already visible with particle sizes from 20 to 25 μm. By using finer particles, this binding effect in the drainage phase occurs with more delay, allowing the particles to be mobile for a longer time, sufficient to reach the dispersed flows and form the indications.

For more than 65 years, CGM CIGIEMME S.p.A. has been designing, developing and manufacturing all types of magnetic particle testing equipment: from small portable devices to automatic in-line systems, from detection products to accessories and control instruments. The offer is completed with the entire range of magnetic powders: dye and fluorescent for wet and dry methods.